RUNMA Robotic Arms in the Spotlight at Chinaplas

With the 31st International Exhibition on Plastics and Rubber Industries (CHINAPLAS) coming, the leader of RUNMA had an inspiration – "why not produce our products on scene and demonstrate the entire process of production to participants?" And he thought we could even give those finished products to regular and potential customers at the exhibition. Actions speak louder than words. Once that's settled, we had contacted 2 industry counterparts, namely Renxing Machine and Huayang Furniture, and talked to them about the idea. Surprisingly, they appreciated it and did not hesitate to join us. At the exhibition, with Huayang providing materials and Renxing showing their machines, Runma employed its robotic arms to produce a waste can. Specifically, we determined and set beforehand the mold of our waste can, then we utilized the automated system to put materials into the machine provided by Renxing, followed by a series of automated processing, finally we got our waste can.

Next, we put "clothes" on that trash can, with the help of the customized automated in-film labeling system of the robotic arm. Look how beautiful it was!

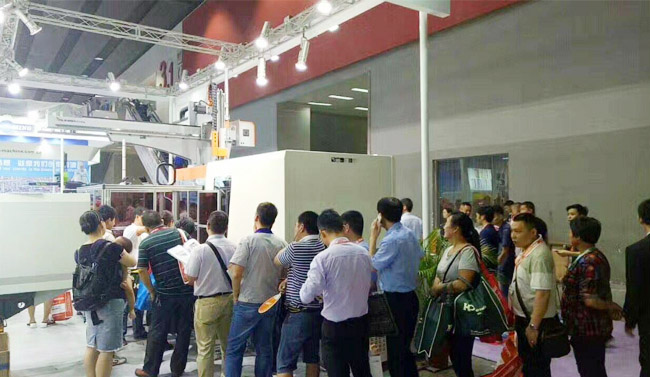

Good products plus artistic production attracted many people, who even waited in a long queue. Our booth was so crowed!

Then I would like to introduce to you the pros and cons of manual production. Without robotic arms, workers have to bring out the waste bin from the mold by hand. But that is really dangerous, for the mold is still on operation. And workers cannot predict how long the production will last, which leads to waste of time. What's more, labor cost is getting higher and higher, and gradually becomes a burden for companies. Not to mention that workers have great uncertainties in their work, as inevitably they will fall ill, ask for leave or even be disobedient. But don't worry, you can get all these problems solved with RUNMA robotic arms that are equipped with the automated system. Robotic arms can work around the clock with stable work time and excellent performance. In addition, we produce custom robotic arms accodring to customer needs. If you need any further information on robotic arms, please do not hesitate to call us or leave us a message on our website!