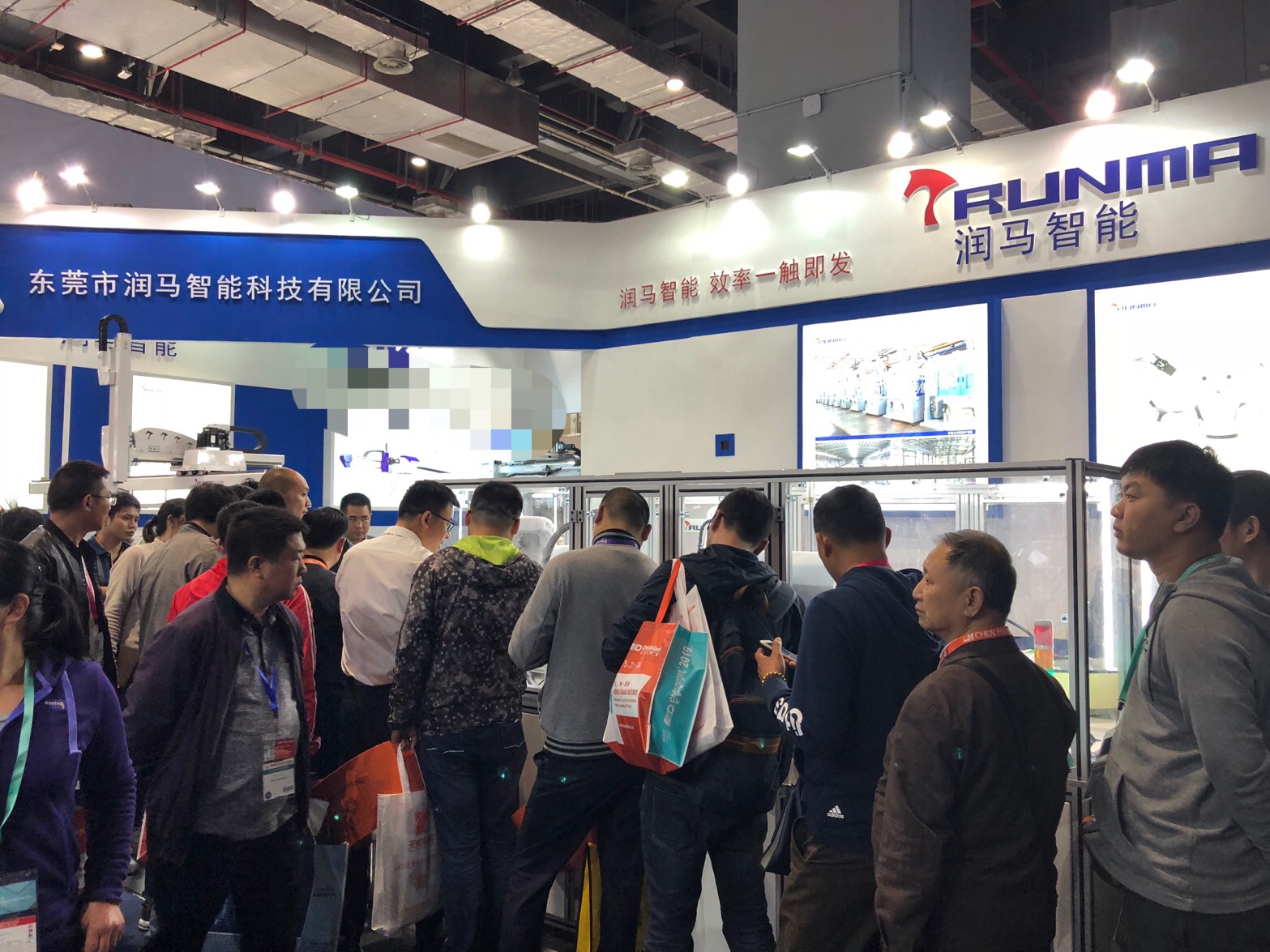

In April, RUNMA actively participated in Chinaplas as always, having showcased six sets of robotic arms altogether, including a single 5-axis robotic arm and an automated assembly system (euipped with fidget spinners). People crowded around our booth from the moment the show began.

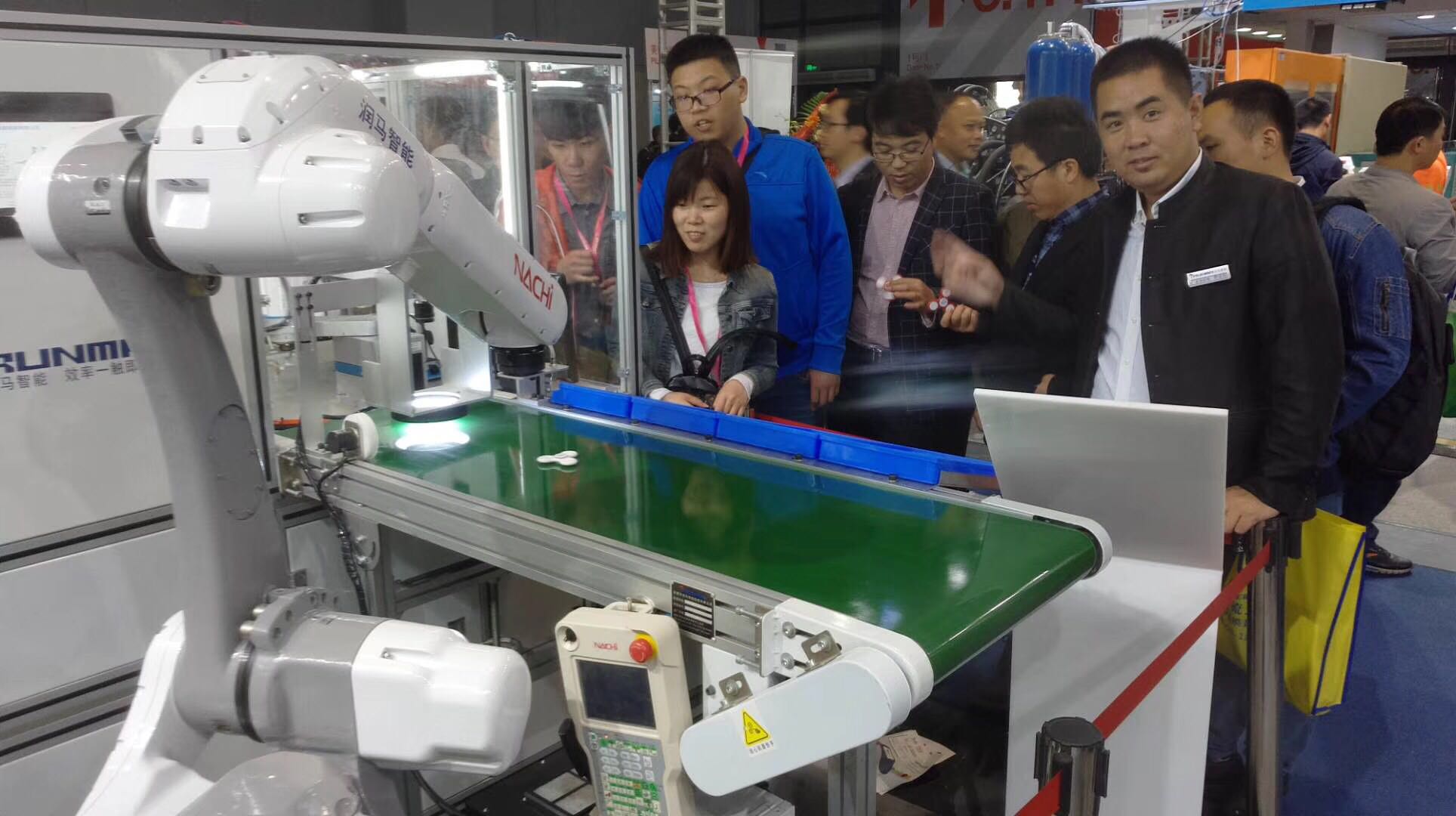

Single 5-axis Robotic Arm

With the BC axis added to the original bull-head 3-axis robotic arm, our single 5-axis robotic arm can meet the demand for complicated removal and palletizer handling. In addition, there is a quick fixture change device at the bottom, which contributes to a wider range of application of the robotic arm.

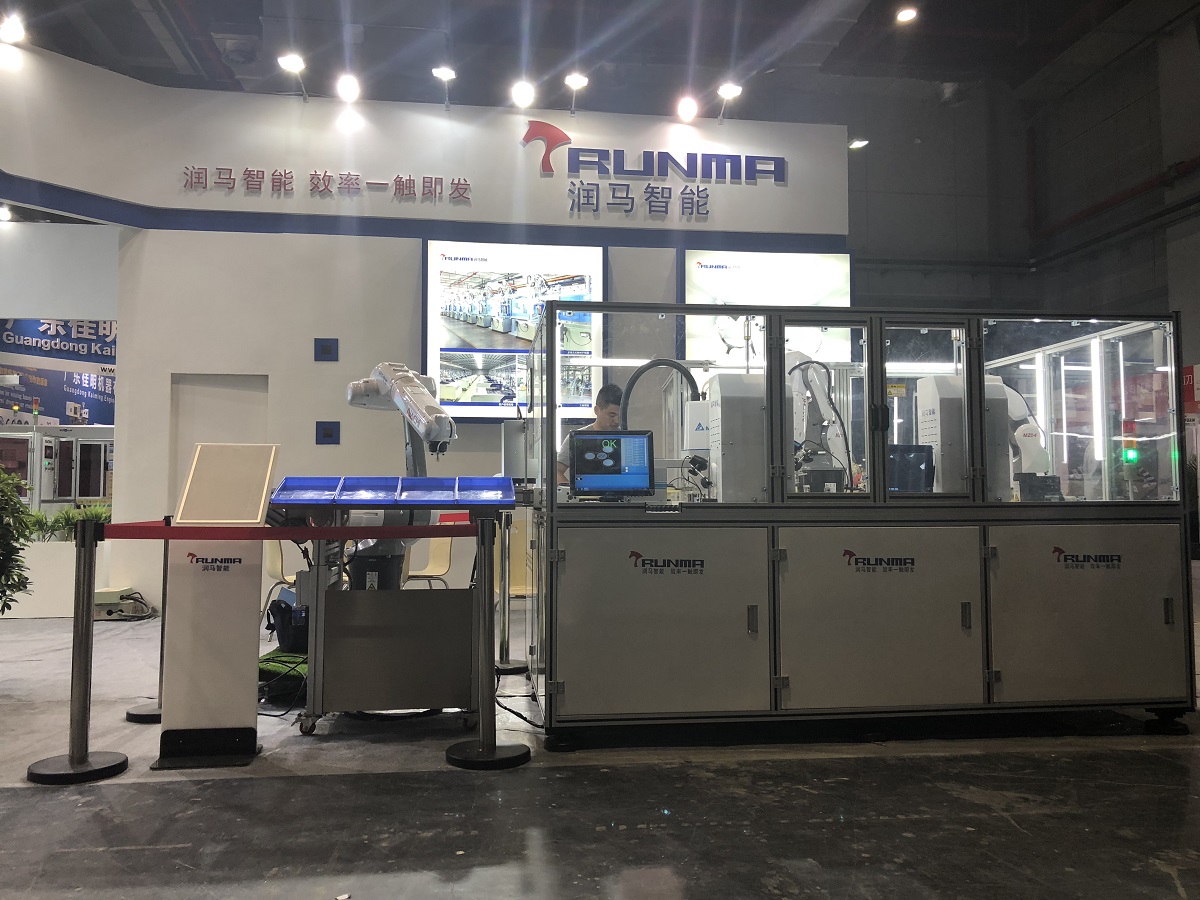

Automated Assembly System (Euipped with Fidget Spinners)

With an advanced robot system and Mitsubishi PLC programming, the automated assembly system is simple and convenient, has excellent performance and boasts a user interface that is easy to operate. In regard to product testing, it uses high-sensitivity optical fiber to check and send signals to the robot to perform loading. The fixture that has a detection system at the bottom of the robotic arm, if does not get loading materials, will send an alarm signal through tricolour light. That is flexible and reliable. Besides, the mold monitor detects in real time whether there is foreign matter on the platen mold or whether finished products. The CCD visual inspection system for end-of-line test carries out real-time monitoring to distingusih different colors and angles of products, and gives feedback to the robot that then sort them into different containers. The automated assembly system is stable and smooth throughout the entire process.

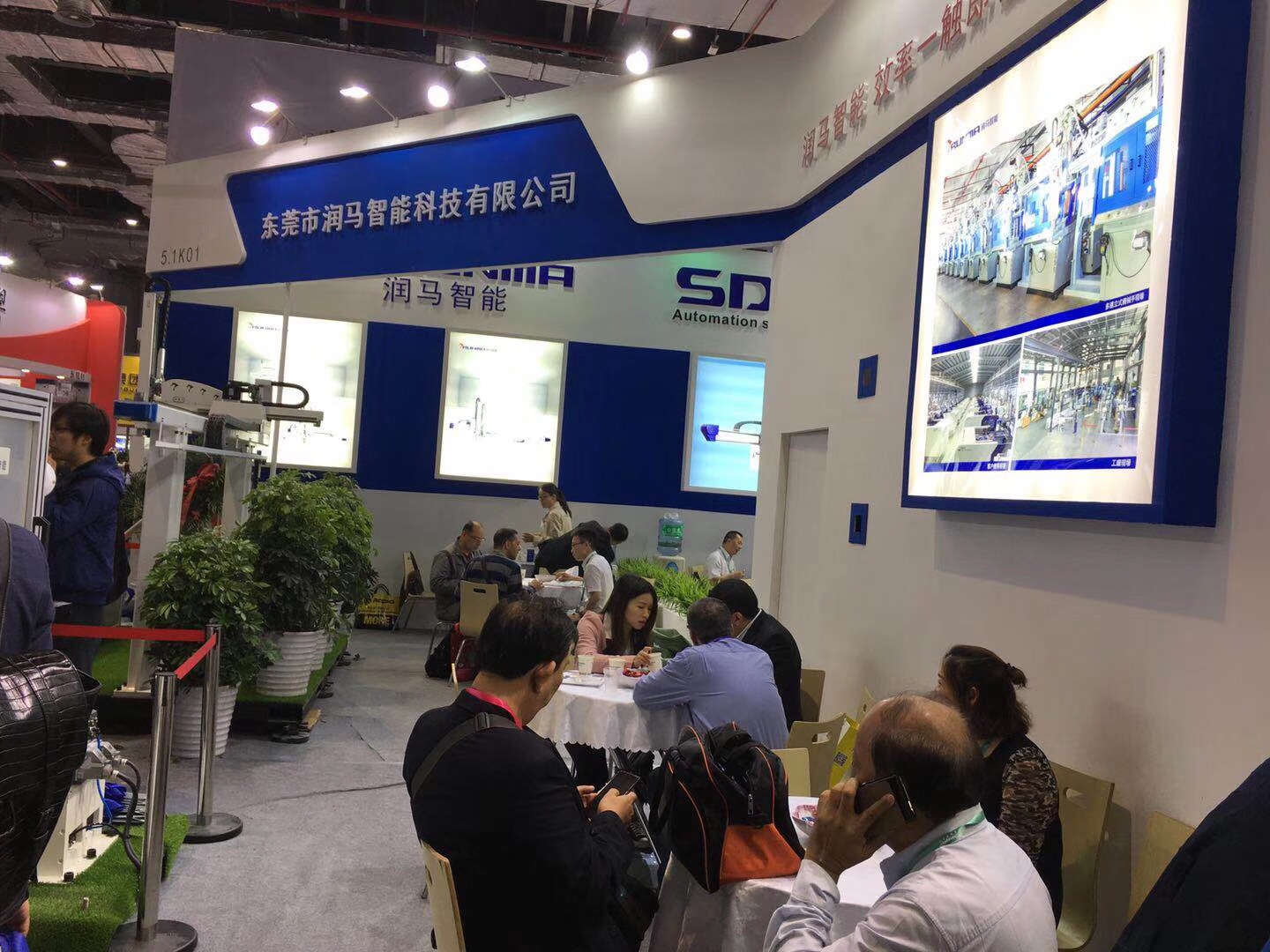

Exchanging Ideas with Customers at Home and Abroad