Gear transmission is one of the most widely used transmission forms in mechanical transmission. It has the advantages of accurate transmission, high efficiency, compact structure, reliable operation and long service life. Gear transmission can be divided into many different types according to different standards.

Advantages:

1. Compact structure, suitable for short-distance transmission

2. Wide applicable circumferential speed and power range

3. Accurate and stable transmission ratio and high efficiency

4. High working reliability and long service life

5. Transmission among parallel axes, intersecting axes at any angle and staggered axes at any angle can be realized.

Disadvantages:

1. Require higher manufacturing and installation accuracy and higher cost.

2. Not suitable for long-distance transmission between two shafts

3. No overload protection

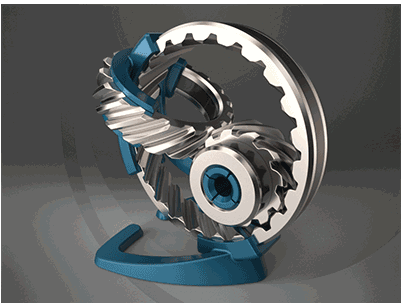

Turbo-rod drive

It is suitable for the motion and power between two axes which are vertical and disjoint in space.

Advantages:

1. Large transmission ratio

2. Compact structure and size

Disadvantages:

Large axial force, easy heating, low efficiency, only one-way transmission.

The main parameters of turbo-rod transmission are:

Modulus

Pressure angle

Worm gear graduation circle

Worm graduation circle

Lead

Worm gear number

Number of worm heads

Transmission ratio, etc.

Belt Drive

A belt drive is a kind of mechanical drive that uses a flexible belt tensioner on a pulley to move or transmit power. Belt drive usually consists of a driving wheel, a driven wheel and an endless belt group tensioned on the two wheels.

Advantages:

1. Suitable for transmission with a large center distance between two shafts, the belt has good flexibility, which can alleviate impact and absorb vibration.

2. Slip during overload to prevent damage to other parts.

3. Simple structure and low cost

Disadvantages:

1. The external dimension of the transmission is large.

2. Tensioning device is required.

3. Due to slippage, a fixed transmission ratio cannot be guaranteed. 4. The life of the belt is short.

5. The transmission efficiency is low.

Chain Transmission

Chain drive is a transmission mode that transmits the movement and power of the driving sprocket with a special tooth shape to the driven sprocket with a special tooth shape through the chain. It comprises a driving chain, a driven chain and an endless chain.

Advantages:

1. Compared with the belt drive, it has no elastic sliding and slipping phenomenon but an accurate average transmission ratio, reliable operation and high efficiency.

2. Large transmission power, strong overload capacity and small transmission size under the same working condition

3. The required tension is small and the pressure acting on the shaft is small.

4. Able to work in harsh environments such as high temperature, humidity, dust and pollution.

5. Compared with gear drive, chain drive has lower requirements on manufacturing and installation accuracy.

6. When the center distance is large, the transmission structure is simple.

Disadvantages:

1. It can only be used for transmission between two parallel shafts. 2. High cost, easy wear and elongation, poor transmission stability 3. Additional dynamic load, vibration, impact and noise will be generated during operation, so it is not suitable for rapid reverse transmission.

Electric drive refers to the use of electric motors to convert electrical energy into mechanical energy to drive various types of production machinery, transportation vehicles and articles that need to move in life.

The main features of the electric drive are:

1) High precision

Servo motor is the power source, which is composed of ball screw and synchronous belt, etc. It has a simple structure and high efficiency. Its repetition precision error is 0.01%.

2) Energy-saving

The energy released in the deceleration stage of the working cycle can be converted into electric energy for reuse, thus reducing the operation cost, and the connected electric equipment is only 25% of the electric equipment required for hydraulic drive.

3) Precise control

The precise control is realized according to the set parameters. With the technical support of high-precision sensors, metering devices and computers, the control precision can greatly exceed that achieved by other control methods.

4) Improve the environmental protection level

Due to the reduction of energy varieties and optimized performance, the pollution sources and noise are reduced, which provides a better guarantee for the environmental protection work of factories.

5) Noise reduction

Its operating noise value is lower than 70 dB, which is about 2/3 of the noise value of the hydraulic injection molding machine.

6) Cost saving

This machine eliminates the cost of hydraulic oil and troubles caused by it, without hard pipes or soft throats, and does not need to cool the hydraulic oil, thus greatly reducing the cost of cooling water, etc.